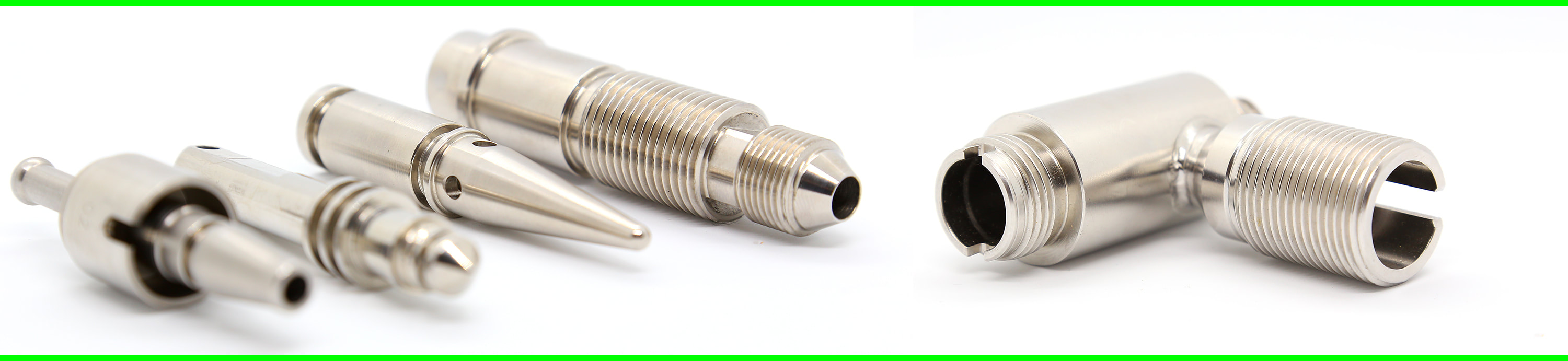

High Quality Precision Engineering

With fourth generation and almost 50 years in the industry, Mintdale is constantly investing in high-tech machinery, CAD / CAM technology, maintaining levels of time served skilled engineers who can help with design-for-manufacture, experienced administrators and factory support personnel, supplying competitively priced products and providing excellent quality to key industry sectors.

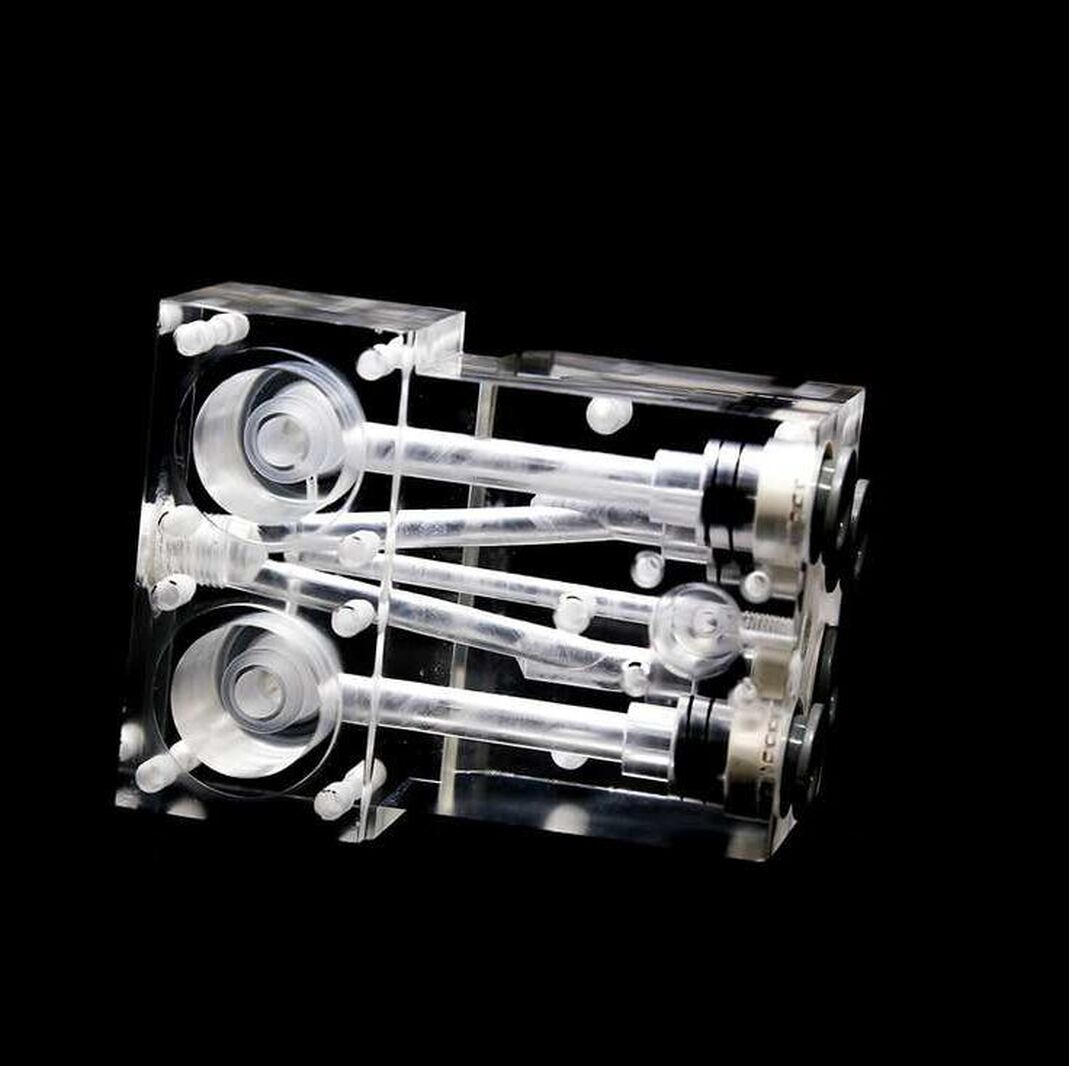

State of the Art Machinery

Mintdale have continually aspired to work to improve their machinery to the latest standards and using the most high-tech technology, enabling development of methods of machining a product in the most efficient way, ideally in one-hit, incorporating the latest technology, ideas, and features.

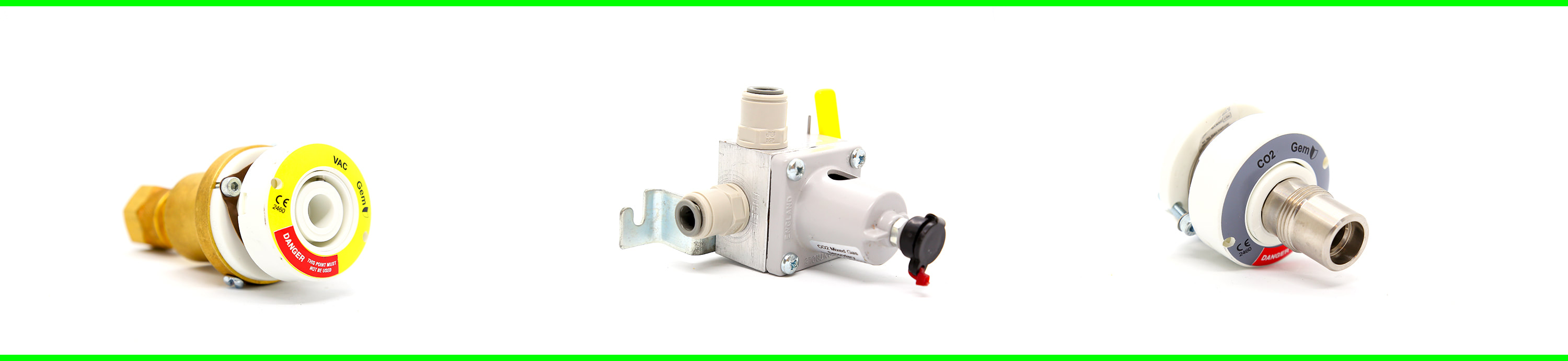

Subcontract Machining and Manufacturing

Over the years Mintdale has expanded its services to adapt to customers’ needs, we supply CNC turned, CNC milled components, offering induction brazing, clean assembly and many other services, supplying volume production as well as Kan Ban, consignment stock and call off supply to suit customer requirements.

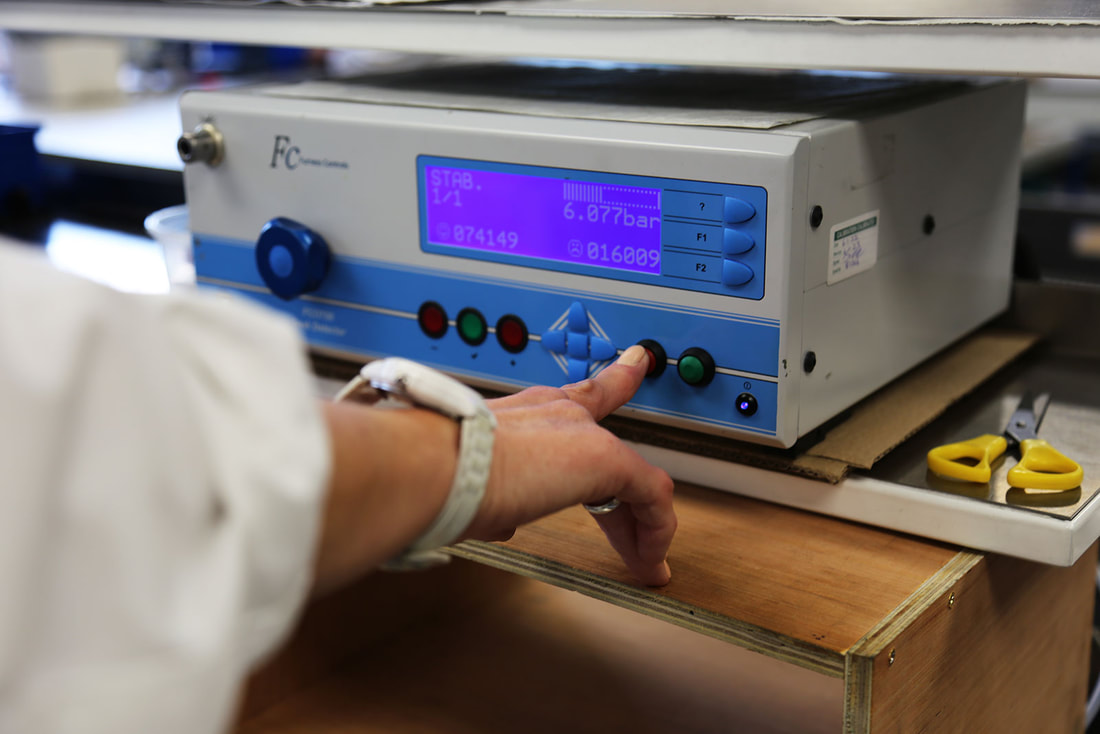

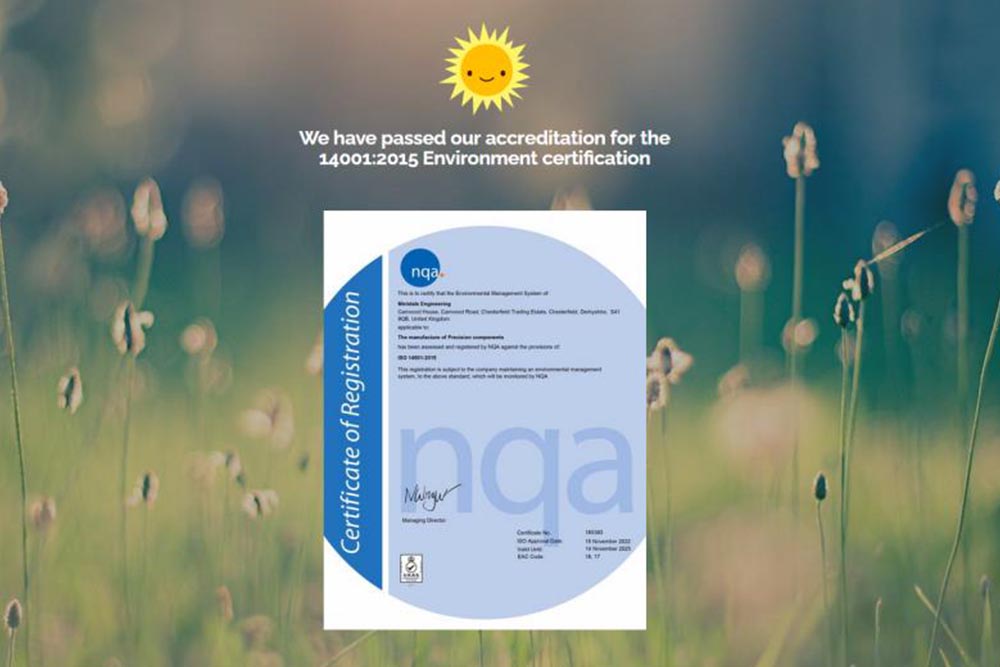

Quality Assured Management System

Mintdale work proficiently and successfully to ISO 9001:2015, a UKAS worldwide approved quality management system accreditation, this enables us to consistently satisfy customers requirements, and enables Mintdale to thrive with continuing repeat orders, new enquiries and customers. The system has been used by Mintdale and approved by our accreditor for nearly 30 years.

Customer Service Excellence

Mintdale are committed to provide a pleasant, professional and efficient service to customers old and new, guaranteeing requested delivery needs with flexibility of service when required.