High Quality Precision Engineering

With fourth generation and almost 50 years in the industry, Mintdale is constantly investing in high-tech machinery, CAD / CAM technology, maintaining levels of time served skilled engineers who can help with design-for-manufacture, experienced administrators and factory support personnel, supplying competitively priced products and providing excellent quality to key industry sectors.

State of the Art Machinery

Mintdale have continually aspired to work to improve their machinery to the latest standards and using the most high-tech technology, enabling development of methods of machining a product in the most efficient way, ideally in one-hit, incorporating the latest technology, ideas, and features.

Subcontract Machining and Manufacturing

Over the years Mintdale has expanded its services to adapt to customers’ needs, they supply CNC turned, CNC milled components, offering induction brazing, clean assembly and many other services, supplying volume production as well as Kan Ban, consignment stock and call off supply to suit customer requirements.

Quality Assured Management System

Mintdale work proficiently and successfully to ISO 9001:2015, a UKAS worldwide approved quality management system accreditation, this enables them to consistently satisfy customers requirements, and enables Mintdale to thrive with continuing repeat orders, new enquiries and customers. The system has been used by Mintdale and approved by our accreditor for nearly 30 years.

Customer Service Excellence

Mintdale are committed to provide a pleasant, professional and efficient service to customers old and new, guaranteeing requested delivery needs with flexibility of service when required, working alongside their trusted external supply chain partners to satisfy valued customers production line needs. We endeavour to answer the phone within 3 rings.

CNC Turning

During CNC turning, a chuck or specialized clamp holds bars of material and, as they are rotated, a cutting tool is fed to the piece to remove material to create a specific shape.Our machines can move up to 9-axis for more complex items that can be completed in one hit.The majority of their CNC turning lathes are bar fed and can work 24/7 with some materials.The chuck machine is loaded manually and machined to a pre-set program. CNC turning capacity ranges from 6mm to 80mm diameter / hexagon on bar fed machines. However, we can CNC turn down to 1mm diameter if required. Chuck machine capacity is up to 250mm diameter / hexagon. Maximum turning length is 250mm.

Up to 9 Axis - 6mm diameter / hexagon minimum – bar fed

however we can machine down to 1mm diameter

80mm diameter maximum / 2.72” hexagon maximum – bar fed

250mm diameter / hexagon maximum – chuck machine

250mm maximum length

Up to 9 Axis - 6mm diameter / hexagon minimum – bar fed

however we can machine down to 1mm diameter

80mm diameter maximum / 2.72” hexagon maximum – bar fed

250mm diameter / hexagon maximum – chuck machine

250mm maximum length

CNC Milling

During CNC milling a cutting tool works on and around a stationary workpiece or boring and tapping tools work inside the workpiece, these machines also have multi-axis capacity for more complex machining.CNC milling capacity table size is 350mm x 900mm.Maximum working height is 500mm.

Multi Axis

Complex machining

350mm maximum table depth

900mm maximum table width

500mm maximum working height

Multi Axis

Complex machining

350mm maximum table depth

900mm maximum table width

500mm maximum working height

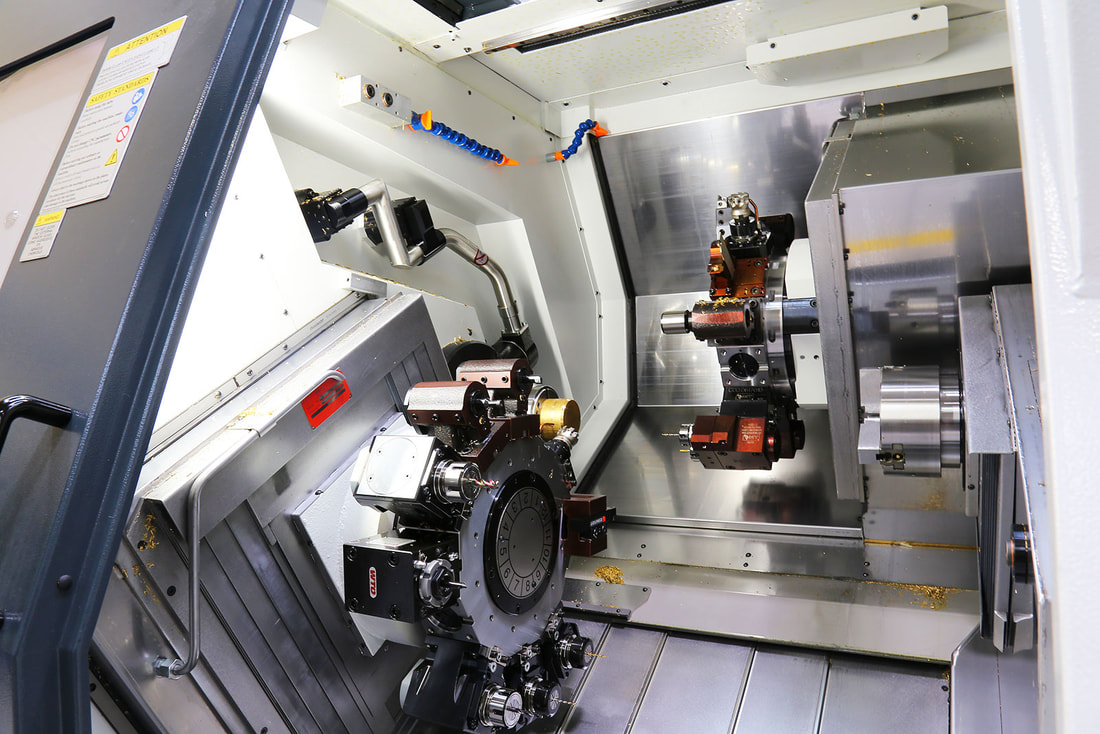

CNC Mill/Turn Machines

A mill/turn machine is a hybrid CNC machine that combines both milling (tool rotating) and turning (workpiece rotating) functionalities into one fast, powerful, and flexible machine that can complete complex operations faster and with greater accuracy than traditional machining technologies. The machines can machine from 6mm up to 80mm diameter with a maximum length of 200mm approximately.

Milled / turned in one hit

Fast, powerful and flexible

6mm diameter / hexagon minimum

80mm diameter / hexagon maximum

200mm maximum length

Milled / turned in one hit

Fast, powerful and flexible

6mm diameter / hexagon minimum

80mm diameter / hexagon maximum

200mm maximum length

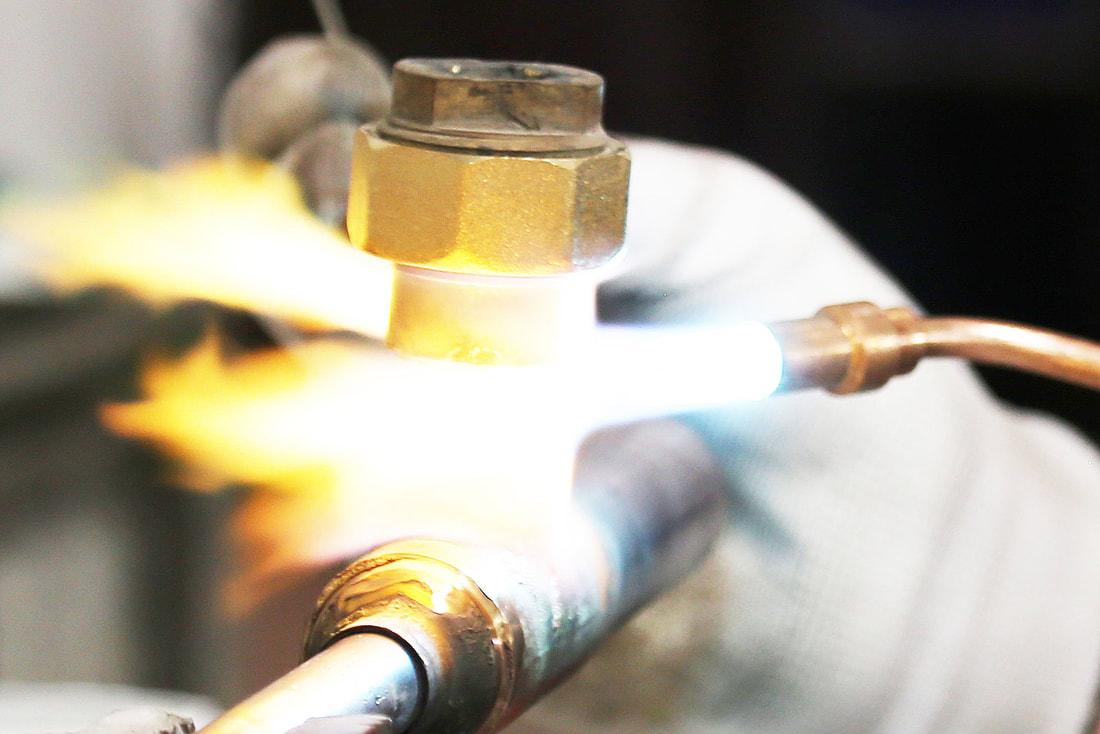

Induction Brazing

Induction brazing is when two or more materials are joined together by a filler metal that has a lower melting point than the base materials using induction heating. Mintdale uses twin head induction brazing Safebraze systems featuring low voltage operator safe coils, incorporating fume extraction systems and PLC multi profile time and power controls. They braze copper to copper or copper to brass. The benefits of induction brazing systems include: direct localised heating of only the joint area, minimal heat-affected zone, uniform heating, high quality leak-proof joints, accurate, repeatable heat transfer, reduced scale formation, quicker cycle times, reduced risk of over-heating. They also gas braze and hand braze for more technical or larger items.

Copper to Copper

Copper to Brass

Uniform repeatable heat transfer

Leak proof joints

Gas and hand brazing

Copper to Copper

Copper to Brass

Uniform repeatable heat transfer

Leak proof joints

Gas and hand brazing

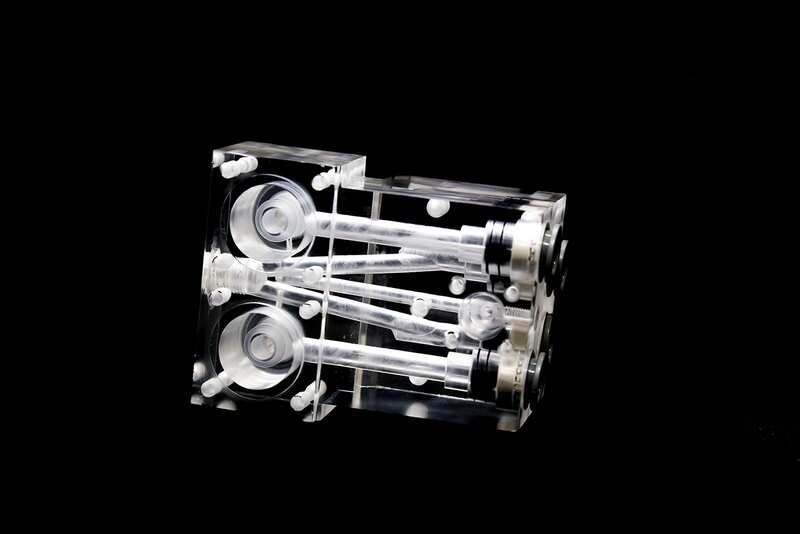

Clean Assembly

Our clean room facility offers the ability for our operators to assemble, sub-assemble and final assemble parts for any industry including medical and drinks dispense.The area has been created to a level of cleanliness required to assemble to medical and drinks dispense standards. Customer’s products are ultrasonically degreased prior to assembly.

Sub Assemble

Final Assemble

Cleanliness to medical standards

Ultrasonic degreasing

Sub Assemble

Final Assemble

Cleanliness to medical standards

Ultrasonic degreasing

Leak Testing

Leak testing is the process of checking a system for leaks or defects in products, to ensure the proper function and maintenance of industrial systems and pipelines. Within the clean room Mintdale also offer a leak testing facility post assembly having invested in the latest leak testing technology, we can test up to 8 items at one push of a button. Items are packaged in grip seal or heat-sealed bags ready to be despatched and can be labelled or autobag printed with part numbers or barcodes to the customer’s requirements.

Checks for leaks or defects

Used for industrial systems and pipelines

Latest leak testing technology

Leak testing post assembly

Test up to 8 items at once

Checks for leaks or defects

Used for industrial systems and pipelines

Latest leak testing technology

Leak testing post assembly

Test up to 8 items at once

Other Services

Include cutting material to size, de-burring, de-greasing, drilling, grinding, linishing, marking, measuring, milling, turning, pressing, stamping, ultrasonic de-greasing, vibrator de-burring and welding

"Mintdale have continually aspired to work to improve our machinery to the latest standards and using the most high-tech technology, enabling development of methods of machining a product in the most efficient way, ideally in one-hit, incorporating the latest technology, ideas, and features.”